GENERAL INFORMATION

The EPR and PPM Regulations were both gazetted in 2024 to manage post-consumer materials and flexible packaging respectively. Below is a summary of the two regulations.

| Regulation | Law | Gazettement | Application |

| The Environmental Management and Coordination (Management and Control of Plastic Packaging Materials) Regulations, 2024 | Environment Management and Coordination Act | Legal Notice 184, 2024 Gazette Vol. CXXVI – No. 213 on 6 December 2024 | Plastic Carrier Bags, Flat Bags, Plastic Film Plastic Packaging materials on Imported Products |

| Extended Producer Responsibility Regulations, 2024 | Sustainable Waste Management Act, 2022 | Special Issue: Kenya Gazette Supplement No. 196 Legislative Supplement No. 85 4th November 2024 | All Products |

Difference between Extended Producer Responsibility (EPR) Regulations and Plastic Packaging Materials (PPM)Regulations

1. Items listed under the Plastic Packaging Materials (PPM) Regulations

Materials not covered under PPM Regulations

2. Do the PPM Regulations duplicate the efforts of the EPR Regulations?

Each regulation responds to a different policy and environmental need:

3. Requirements for Plastic Packaging Materials Compliance

4. Implementation of the Environmental Management and Coordination (Plastic Packaging Materials) Regulations, 2024

These regulations came into effect through a public notice issued on the 28th of February 2025. Each producer with an existing Plastic Clearance License will be required to renew their application with the Authority by 30th August 2025. All existing licenses will be rendered invalid by this date for the listed types of companies:

Summary of actors applicable to the Plastic Packaging Materials Regulations

| Role | Required License |

| Manufacturer | License to manufacture plastic packaging |

| Importer | License to import plastic packaging |

| Exporter | License to export plastic packaging |

| User/Brand Owner | License to use plastic packaging (for both industrial and non-industrial purposes) |

5. Plastic Bag Labelling Requirements

Locally Packed Products

All flexible plastic packaging must have permanent and legible print with the following:

PP

Labelling for Imported Products

Imported plastic-packaged products must clearly indicate:

PP OR

BOPP+MOPP+PE

Sellers of Plastic Packaging for Retail e.g. supermarkets stocking liner bags

PP OR

BOPP+MOPP+PE

Even if you are not directly packing the product, the packaging must show both the packer and the product owner.

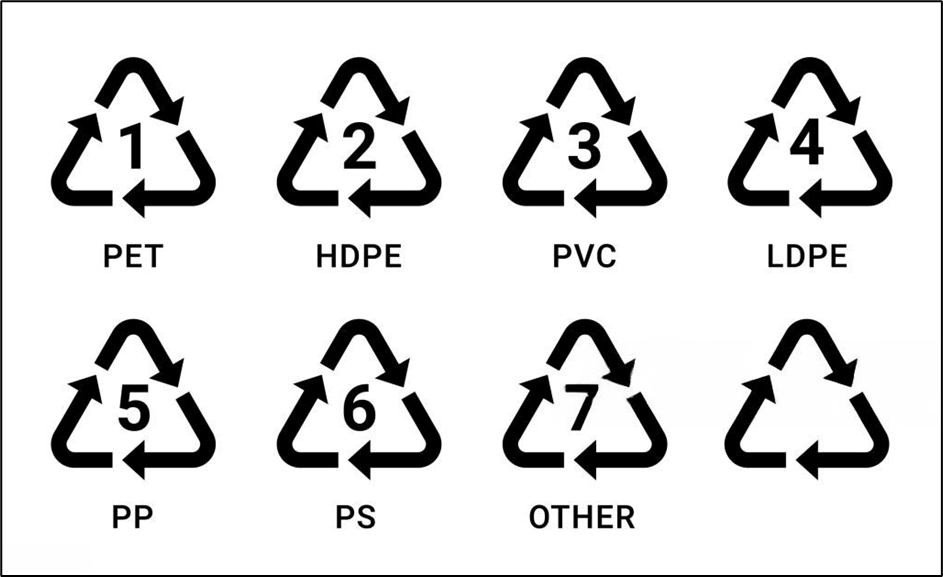

Different types of Resin Identification Codes for packaging

♻️ PLASTIC RESIN IDENTIFICATION CODES – QUICK REFERENCE GUIDE

| Code | Abbreviation | Full Name | Common Use Cases |

| 1 | PET | Polyethylene Terephthalate | PET Flexibles |

| 2 | HDPE | High-Density Polyethylene | HDPE Plastic bags, cereal box liners, industrial liners |

| 3 | PVC | Polyvinyl Chloride | PVC Flexible Film |

| 4 | LDPE | Low-Density Polyethylene | Bread bags, frozen food bags, shrink wrap, LLDPE Film flexible packaging |

| 5 | PP | Polypropylene | BOPP Film Flexible packaging, BOPP Shrink wraps, BOPP Laminated PP Woven Bags, BOPP Laminated PP Non- Woven Bags, PP Woven bags & PP Non-woven bags, PP Film flexible packaging, PP Shrink wrap |

| 6 | PS | Polystyrene | Too brittle and mostly used for rigid, not flexible packaging |

| 7 | OTHER | Mixed/Other (e.g. multilayers) | Plastic Laminates BOPP + PE PET + PE BOPP + CPP Alu- Plastic Laminates PET + AL + PE, BOPP + AL + PE Paper Plastic Laminates Paper + PE Paper + BOPP |

NB: Resin Code 7 are for two or more polymers (e.g. PET + PE, BOPP + MET BOPP), making them incompatible with any single code. For packaging that falls under Resin Code 7, instead of using Other, you’ll indicate as:

BOPP+MOPP+PE

to describe the components of your plastic packaging

Q&A

Q1. What are the steps I should take to ensure I am fully compliant with NEMA

EPR and Plastic Packaging Materials Compliance Fees

| Applications | Procedure | Use/ Function | Fees | Approval Time | Issued | |

| 1 | PRO Registration | Declaration of annual weight of all packaging sold (non-industrial) into the country | All products and their packaging | Annual Membership Fee | Up to 2 Business Days | PRO Certificate Summary EPR Plan |

| 2 | Producer Registration | NEMA eCitizen Portal | All products and packaging sold in the Kenyan market | One off payment 5000KES | Up to 21 Business Days | Individual Producer Registration Number |

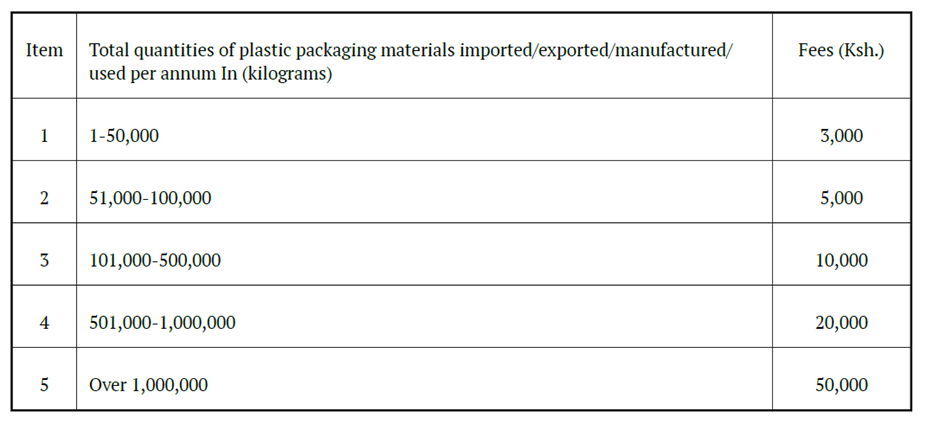

| 3 | Plastic Clearance | NEMA Licensing Portal | All flexible plastic packaging used for industrial or non-industrial purposes (retail) | Fee Schedule listed below | Up to 15 Business Days | Plastic Clearance Certificate |

| 4 | EPR Import Fee | NEMA eCitizen Portal | All imported goods and products for industrial and non-industrial use (retail/ personal use) | 150KES per largest packing unit | Up to 21 Business Days | EPR Import Fee Certificate |

| 5 | Monthly EPR Fees | PAKPRO | All products and packaging sold (non-industrial use) into the Kenyan market | PAKPRO EPR Fee Guide | Invoiced within 2 Business Days | Annual Waste Recovery Report |

NB: All NEMA licenses and PRN are to be collected physically at their HQ offices. NEMA is expected to be fully integrated digitally in the next one month.

Q2. If we import through an agent, but the product is branded in our name, are we required to register ourselves, or is the responsibility on the agent to register?

The entity named in the Import Declaration Form (IDF)—whether it’s the agent or the brand owner—is the one responsible for applying and paying for the license.

Each importer is responsible for:

Q3. Is there a template for this application?

After the webinar, will PAKPRO members receive the following documents to support their compliance journey:

Upload your PRO certificate to the section requiring your EPR plan. NEMA will engage your PRO for the implementation of the EPR plan.

We strongly encourage you to start the process early. As with all online portals, delays and technical issues tend to arise closer to the deadline—so the earlier you act, the smoother your experience will be.

Q4. Is submission of physical samples still required?

No, physical samples are no longer required.

Q5. Why can’t NEMA consolidate all the registrations into one system?

NEMA highlighted that there are several different streams of plastic regulated under the EPR. To manage this complexity, it was considered more effective to regulate flexible plastic packaging materials separately, since they are the major contributors to environmental pollution across various ecosystems.

PAKPRO is currently engaging with NEMA on the ease of doing business to develop a simpler compliance regime.

Q6. Do we all need to upload our EPR Plans

As per NEMA, each producer will upload their PRO certificate on the Plastic Clearance portal.

The Authority will engage the PROs to confirm compliance of their submitted EPR plans. PAKPRO will issue each company with a summarised EPR plan for your record keeping.

Q7. If I manufacture or supply plastic packaging materials to another factory for industrial use—and not directly to the final consumer—am I still required to apply for a plastic packaging clearance license from NEMA?

✅ Yes — you will still need to apply for Plastic Packaging Clearance.

Even if you’re supplying plastic packaging materials (PPM) to another factory and not directly to the final consumer, you are still required to apply for a Plastic Clearance License under the Environmental Management and Coordination (Plastic Packaging Materials) Regulations, 2024.

🔍Why?

The regulations apply to all entities involved in the production, importation, use, and distribution of flexible plastic packaging, whether for industrial or non-industrial purposes.

Q8. Can you clarify how the regulations apply to importers of finished goods into Kenya? What are their responsibilities under the current requirements?

According to the regulations, any entity handling plastic packaging material is required to apply for plastic clearance.

This includes importers of finished goods that come with plastic packaging. If the product enters the Kenyan market with plastic packaging, the importer is still responsible for obtaining the necessary clearance.

Under the EPR Regulations:

You are required to pay the EPR Import Fee on all imports each time a consignment is brought into the country on the following:

If they enter the country through a port of entry and are packaged, they are subject to the EPR import fee.

Under the Plastic Packaging Materials Regulations :

If any of those goods — whether raw, intermediate, or finished — contain flexible plastic packaging material, you must apply for plastic clearance license because plastic flat bags and carrier bags are still banned in the country. Any user of flexible plastic bags must obtain a license to import, manufacture, use or distribute.

Q9. Are there any exemptions?

Currently, there are no exemptions under the regulations—even for exporters.

If you are importing goods for the purpose of export, and those goods include plastic packaging materials, you are still required to apply for plastic clearance. The regulations apply to all entities handling plastic packaging, regardless of whether the goods remain in the local market or are exported.

Q10. Where are the initial applications for the PPM Clearance Licence done?

Effective 28th July 2025, all applicants—whether applying for the first time or seeking a renewal—will be required to submit a fresh application under the “New License Application“ category for their License for Plastic Packaging Material via NEMA’s new licensing portal: – https://licensing.nema.go.ke/.

Renewal applications will only be applicable from next year, upon the expiry of the license issued through this initial process.

NB: the old licensing portal on NEMA’s website was decommissioned and licensing for all licences and permits under the Environmental Management and Coordination Act will now be done on the new NEMA portal. Refer to the NEMA public notice on 24.06.2025

If you experience any challenges, you’re encouraged to contact NEMA directly through their landlines or reach out to the plastic clearance desk. PAKPRO will offer its support to all its members if you face any challenges with the NEMA direct line.

Q11. How long will the PPM Division take to issue the new licences?

Applications will be reviewed between 1 – 15 Business Days

Delays may also occur if the applicant hasn’t addressed all application requirements or submitted complete documentation.

If there are issues with the application—such as missing information, incorrect documentation, or labelling that doesn’t meet the requirements—the process may take longer. The speed of license issuance will then depend on how quickly the applicant responds and resolves the issues raised by NEMA.

Q12. Suppose now a new company is using PET bottles—what happens then?

If you’re a new company packaging in PET rigid bottles, you’ll most likely use shrink wrap on your products when sending them to market. In that case:

Q13. Which one comes first?

Do we start with plastic clearance, then move to EPR compliance?

Is there a specific order to follow, or can these processes be done in parallel?

While plastic clearance technically comes after Producer Registration with NEMA, you’re strongly encouraged to start both processes as early as possible to avoid delays—especially since both are done through online portals.

Once you submit your Producer Registration, you’ll need to wait approximately 21 days to receive your Producer Registration Number. Every company in Kenya will eventually need this number.

However, while waiting, if you’re a new company or if you need to renew your license before the 30th of August, you can go ahead and start your plastic clearance application in parallel.

Q14. What is the difference between the EPR application process on the eCitizen platform and the PPM clearance application on the NEMA website?

Yes, there’s a key distinction in where each application is done:

✅ EPR = eCitizen platform

✅Plastic Clearance = NEMA licensing portal

Q15. Regulation 20 requires that the name and contact information of the manufacturer or seller be printed on all plastic packaging materials. For small-sized packaging like chewing gum wrapped in plastic film, how can all these details be incorporated, or is there an approved alternative method such as using an identifiable mark?

For very small packaging like chewing gum wrappers, where it is not feasible to print all the required information, the key requirement is that the outer packaging (e.g., multipack or retail display pack) must clearly display the necessary details. In such cases, an identifiable mark or logo may be accepted in place of full contact details.

Q16. If a group of companies operates through multiple subsidiaries, each handling different product lines, is a separate license required for each subsidiary, or can one license cover the entire group?

Each subsidiary must apply for its own separate license if they are trading with a unique KRA PIN.

Q17. If I have already declared the estimated annual volumes of plastic packaging materials during my application and paid the annual licence fee, will I be required to make any additional payments at the point of entry for each consignment? Also, what documentation or reference is used at the port for each consignment?

Under the EPR Regulations, each consignment will attract 150KES/ number of packing units in the container, each time a shipment arrives at the ports

The plastic clearance license is issued annually as a permit to trade and use flexible plastic packaging.

Q18. Should garbage collection companies that use plastic materials like garbage bags and bin liners also be required to have an EPR Plan?

Garbage transport companies are required to develop an EPR plan. This is because garbage bags and bin liners will bear their brand names, and as suppliers of these PPMs to their customers, they will need to demonstrate how they will manage the same.

Q19. If a company changes its name and they need to renew their license, is this now termed as a new application, or do they still do a renewal with an attachment of their certificate of incorporation?

If a company changes its name, it does not need to make a new application. They should proceed with a renewal and attach both the old and new certificates of incorporation. NEMA will then process a variation and update the license under the new name.

Q20. Does the portal have a payment option?

Yes. The new licensing portal offers multiple payment options for your convenience, making it easier to complete transactions securely and efficiently.